Basis Weight

The weight in pounds of 500 sheets (one ream) of a standard basic size. For example, the standard basic size for text papers is 25×38”. A ream of basis 70 text sheets in that size weighs 70 lbs. The basic size for cover papers is 20×26”. Weighing 500 sheets of any grade of paper in its proper basic size will determine its basis weight. In other words, 500 sheets of 17×22” 24-pound Bond will weigh 24 pounds.

Brightness

Brightness is measured as the percentage of light in a narrow spectral range reflected from the surface of a sheet of paper. It is not necessarily related to color or whiteness. A paper with a brightness of 98 is an extremely bright sheet with almost all light being reflected back to the viewer. Bright white papers illuminate transparent printing inks, giving cleaner, crisper color, and contrasty blacks.

Caliper

Caliper is a measure of paper thickness expressed in thousandths of an inch. The micrometer is used to measure caliper.

Cast Coated

High-gloss coated paper manufactured by casting the coating paper against a highly polished, heated steel drum.

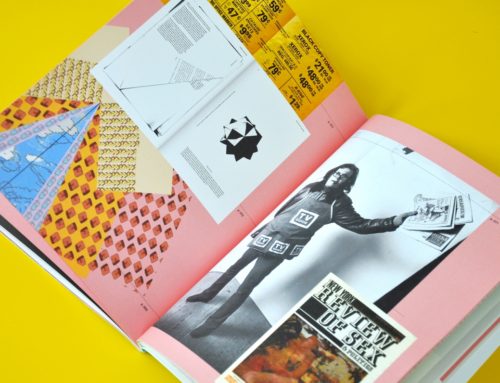

Coated Paper

Made with a surface coating, which allows for maximum smoothness and ink holdout in the printing process. Coated papers are available in a range of finishes from dull to matte, and gloss.

Cover Paper

Also called card stock, these papers are heavyweight coated or uncoated paper with good folding characteristics. Their diverse uses include folders, booklet covers, brochures and pamphlets.

Deckle Edge

Produced in hand-papermaking by drainage under a wooden frame surrounding the hand mould. The rough edges on hand-made and some machine-made papers were originally

considered an imperfection. The deckle edge came back in fashion with the handcraft revival in the last decade of the 19th century.

Formation

Refers to the uniformity and distribution of fibers within a sheet of paper. In a well formed sheet, solid ink coverage will go down smoothly. A poorly formed sheet will exhibit a mottled appearance when printed. Formation can be checked by holding the paper up to a light source: A well formed sheet appears uniform, while in a poorly formed sheet the fibers appear as clumps, giving it a cloudy look.

Grain Direction

As the paper web is carried forward on the machine, the majority of fibers orient themselves in the machine direction. When the web of paper is sheeted, the sheets will be grain long (fibers that follow the long side of the sheet) or grain short (they follow he short side). Grain direction should be considered during the design process for best results during printing, folding, and converting.

Ink Holdout

A characteristic of paper related to its capacity to keep ink sitting on its surface rather than absorbing into the sheet. Better ink holdout produces sharper printed images.

Laid

A linear pattern which is applied by a dandy roll while the paper is still very wet, to mimic the effect of some hand-made papers. The laid dandy roll is comprised of wires that run parallel to the roll’s axis (laid lines), and chain lines, which connect the laid lines and run in the grain direction.

Laser Paper

Very smooth, low-moisture papers manufactured in cut sizes for laser printers and office duplicating equipment. Low moisture prevents paper curling from high heat in laser printers. Note: If your job is designed to run through a laser printer, you should specify laser-compatible offset inks.

Linen Finish

One of the many textured effects that is produced by embossing a web of paper with a patterned steel roll. Embossing takes place off the machine as a separate operation.

Moisture Content

The amount of moisture found in a sheet of paper. If the moisture content in a sheet is too high or too low, the paper can curl or build up static, which affects the way it runs through a press, printer or copier.

M-Weight

The weight, in pounds, of 1000 sheets of paper of a given size.

Offset Paper

Uncoated paper designed for use in offset lithography. Important properties include good internal bonding, high surface strength, dimensional stability, lack of curl, and freedom from foreign surface material.

Opacity

Measure of the percentage of light passage through a sheet of paper. The more opaque a paper is, the less show-through there will be from printing on the sheet below. Basis weight, brightness, type of fibers, fillers, coatings, and formation all influence opacity. Generally, opacity and brightness are inversely related to each other: the brighter the paper, the less opaque. Mohawk’s revolutionary Inxwell papers provide brightness along with higher opacity. Other factors that affect opacity are bulk, surface smoothness, and shade.

Paper Grade

A system used to classify papers by their common features or content, such as recycled, coated or newsprint papers.

Postconsumer recycled fiber

Fiber recovered for papermaking from postconsumer waste paper.

Postconsumer waste

A material or product that has served its intended use and has been discarded for disposal after passing through the hands of a final user. PCW is a part of the broader category “recycled material”.

Recycled

Papers that contain post-consumer fiber can currently be called recycled. The Federal Executive Order calls for a 30% post-consumer fiber minimum for uncoated papers, and a 10% post-consumer fiber minimum for coated papers.

Renewable energy

Renewable energy is energy that is derived from continuously available sources that do not rely on exhaustible fossil fuels like coal, oil and gas. Examples of renewable energy are wind, solar, hydroelectric, geothermal and ocean tides.

Smoothness

The surface quality of a sheet of paper, related to the flatness of the sheet. Smoothness affects ink and toner receptivity. The Sheffield scale measures smoothness. A higher value typically indicates a rougher sheet. For example, Navajo’s smoothness is 45, whereas vellum offset may have a rating from 200-250.

Uncoated Paper

Paper manufactured with no surface coating. There is a wide variety of grades and levels of quality among uncoated papers.